Everything About Membrane Switch Over: Recognizing Its Style and Performance

When you think regarding the control interfaces in modern tools, membrane buttons frequently come to mind. Allow's explore what collections membrane layer switches over apart from other control systems.

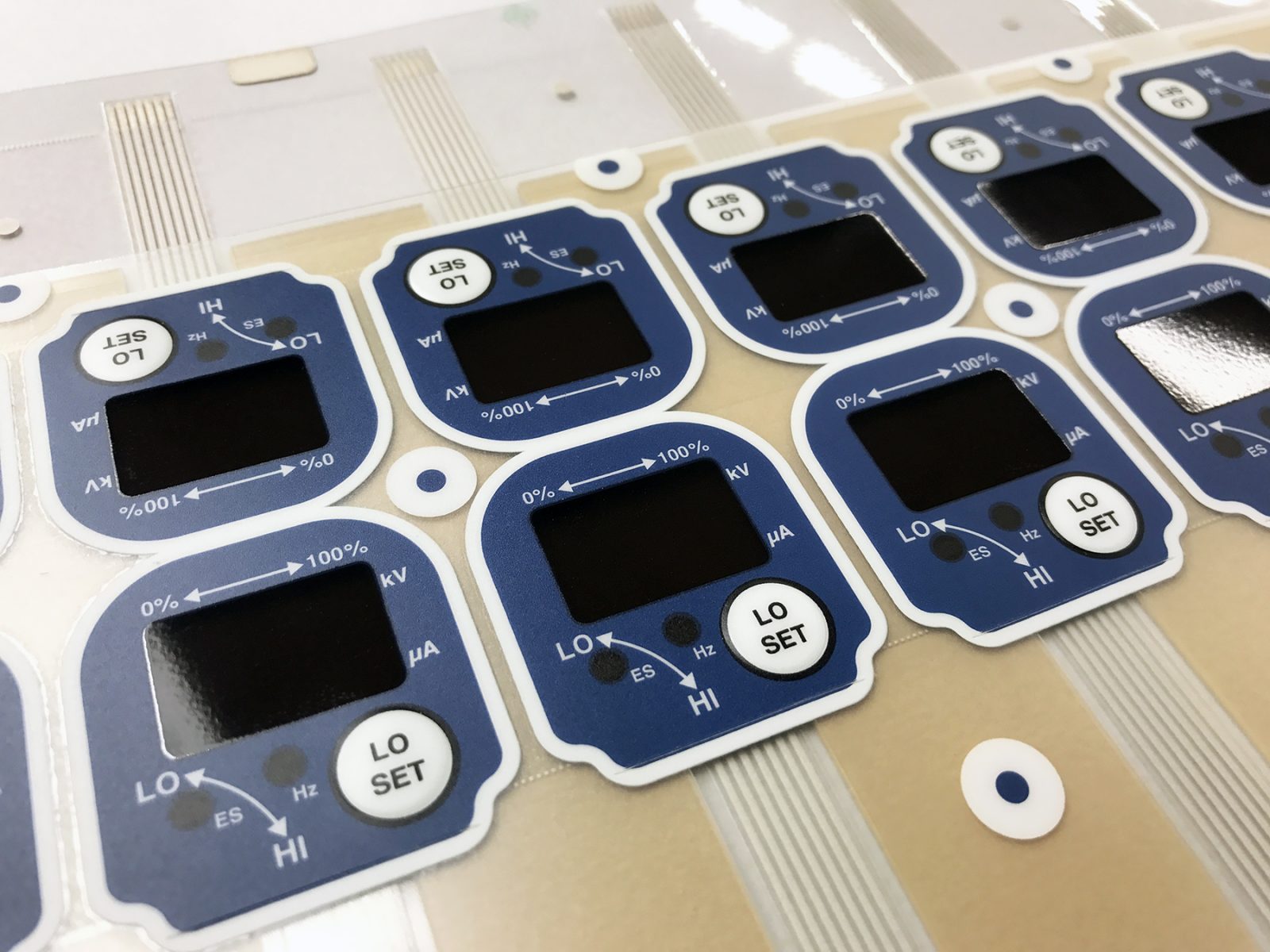

What Are Membrane Switches?

Membrane switches can also be personalized pertaining to form, size, and graphics, enabling makers to create distinct interfaces customized to certain items. Generally, membrane layer buttons play a significant role in boosting user experience throughout a large range of applications.

Just How Membrane Layer Switches Work

When you push a trick on a membrane button, it activates a simple yet efficient mechanism. The top layer, typically made from adaptable material, pushes down onto a conductive layer underneath it. This action bridges the void in between conductive traces, finishing an electrical circuit. As quickly as the circuit closes, it sends out a signal to the device's controller, which analyzes your input.

You'll see that the tactile responses varies based upon the button layout, providing either a soft click or an extra pronounced action. Once you release the trick, the membrane go back to its initial position, resuming the circuit and stopping the signal. This procedure takes place nearly instantaneously, guaranteeing a receptive user experience.

Membrane layer buttons are preferred due to their toughness and resistance to dirt and wetness, making them perfect for different applications, from house home appliances to medical devices. Comprehending this procedure aids you value their prevalent use.

Secret Components of Membrane Switches

Understanding the key parts of membrane buttons is basic for comprehending their performance and design. At the core, you'll locate the visuals overlay, which gives the aesthetic user interface for users. Below that, there's a spacer layer that divides the circuit layers, making sure that they do not make get in touch with until pressed. The circuit layer is where the magic happens; it consists of conductive traces that finish the circuit when you push the button. One more vital aspect is the glue support, permitting the button to follow surfaces safely. The protective layer shields versus ecological elements and wear, prolonging the button's life expectancy. Each component plays a significant duty in ensuring trustworthy performance and user communication. By comprehending these components, you'll get insight into just how membrane switches over operate and their significance in numerous applications.

Materials Made Use Of in Membrane Layer Switch Over Design

The efficiency and sturdiness of membrane layer switches over greatly depend on the products made use of in their layout. You generally encounter polyester and polycarbonate as key substrates because of their superb strength and adaptability. These materials stand up to scrapes and chemicals, making them optimal for demanding atmospheres.

The conductive layers often use silver or carbon, picked for their dependability and conductivity. membrane switch manufacturer. Silver provides remarkable efficiency, while carbon is a cost-efficient alternative. For the overlay, you could consider a matte or shiny coating, relying on your aesthetic needs and user experience

Adhesives play a crucial role too; they bond layers securely and ensure long life. Ensure to select adhesives that endure environmental variables like temperature level and humidity. Don't overlook the importance of a good printing technique for graphics, as it improves both performance and aesthetic charm. Picking the best materials will certainly assure your membrane layer button stands the test of time.

Style Considerations for Membrane Switches

While creating membrane layer buttons, it's essential to take into account various factors that affect their capability and customer experience. Start by concentrating on the format and button size; make sure they're instinctive and easy to browse. Think about the responsive comments you wish to give-- will individuals need a visible click or a softer touch? In addition, think of the materials you'll make use of, as they'll impact longevity and visual appeals.

Do not overlook the graphic layout; clear labeling and shade contrast are site here significant for exposure. Verify your layout accommodates ecological aspects, like moisture or temperature variations, which might influence performance. Remember the relevance of testing prototypes with genuine individuals to collect responses and make required modifications. This repetitive procedure assists you improve the design, verifying it satisfies both practical and aesthetic needs properly. By very carefully considering these elements, you'll create a membrane switch that enhances usability and fulfillment.

Applications of Membrane Layer Buttons

Membrane buttons are flexible components found in different applications, from commercial tools to customer electronics. You'll see their influence in machines that call for long lasting interfaces and in devices that gain from smooth styles. Comprehending these applications helps you value the performance and usefulness of membrane buttons in daily technology.

Industrial Tools Use

When you're looking to enhance the functionality of commercial tools, membrane layer switches supply a trustworthy solution that combines resilience with user-friendly style. These buttons are excellent for harsh environments, giving resistance to dust, moisture, and chemicals. Welcome membrane layer switches to enhance your operations and enhance general performance.

Consumer Electronics Integration

In the domain name of consumer electronic devices, membrane layer switches play an important duty in boosting individual interaction and tool capability. Membrane layer buttons likewise assure toughness and resistance to dirt and moisture, expanding the life-span of your electronics. By picking membrane buttons, you enhance not simply the performance yet also the design of your devices, making day-to-day communications smooth and enjoyable.

Benefits and Downsides of Membrane Switches

While membrane switches offer an array of advantages, they also come with some drawbacks that you ought to take into consideration. One significant advantage is their small style, making them excellent for space-constrained applications.

Nevertheless, there are negative aspects. Membrane buttons can have a much shorter life-span contrasted to mechanical buttons, specifically under hefty use. They can additionally be less tactile, which may affect user responses throughout procedure. If harmed, repairing them can be tough and frequently needs complete substitute. Eventually, their level of sensitivity to extreme temperature levels and environmental conditions might restrict their performance in certain setups. Balancing these benefits and drawbacks will certainly assist you establish if membrane buttons are the ideal suitable for your task.

Regularly Asked Concerns

The Length Of Time Do Membrane Layer Switches Generally Last?

Membrane layer changes normally last in between 5 to one decade, depending on usage and environmental problems. You'll intend to review elements like wear, direct exposure to dampness, and temperature fluctuations to evaluate their long life effectively.

Can Membrane Layer Switches Be Customized for Details Styles?

Yes, you can personalize membrane switches to fit certain layouts (membrane click here for info switch manufacturer). You'll have the freedom to select shades, shapes, and formats that match your task's requirements, ensuring they mix perfectly with your overall aesthetic

What Is the Expense Variety for Membrane Layer Change Production?

The expense variety for membrane layer button manufacturing commonly falls between $1 and $10 each, relying website link on aspects like style intricacy, amount, and products. You can obtain quotes from producers to locate the very best option.

Are Membrane Layer Changes Water Resistant or Resistant?

Membrane buttons can be designed to be water-proof or immune, depending upon products utilized and building approaches. If you need them for damp atmospheres, ensure you specify those needs during the layout procedure.

Just How Do Membrane Layer Switches Over Compare to Traditional Switches?

Membrane buttons are usually thinner and more flexible than typical buttons, supplying a streamlined style. They're often less complicated to cleanse and incorporate, however may not offer the responsive comments you're utilized to with mechanical options.

Conclusion